Summary

Developing my own gear has always been a passion, and a side project / backburner project that evolved over time.

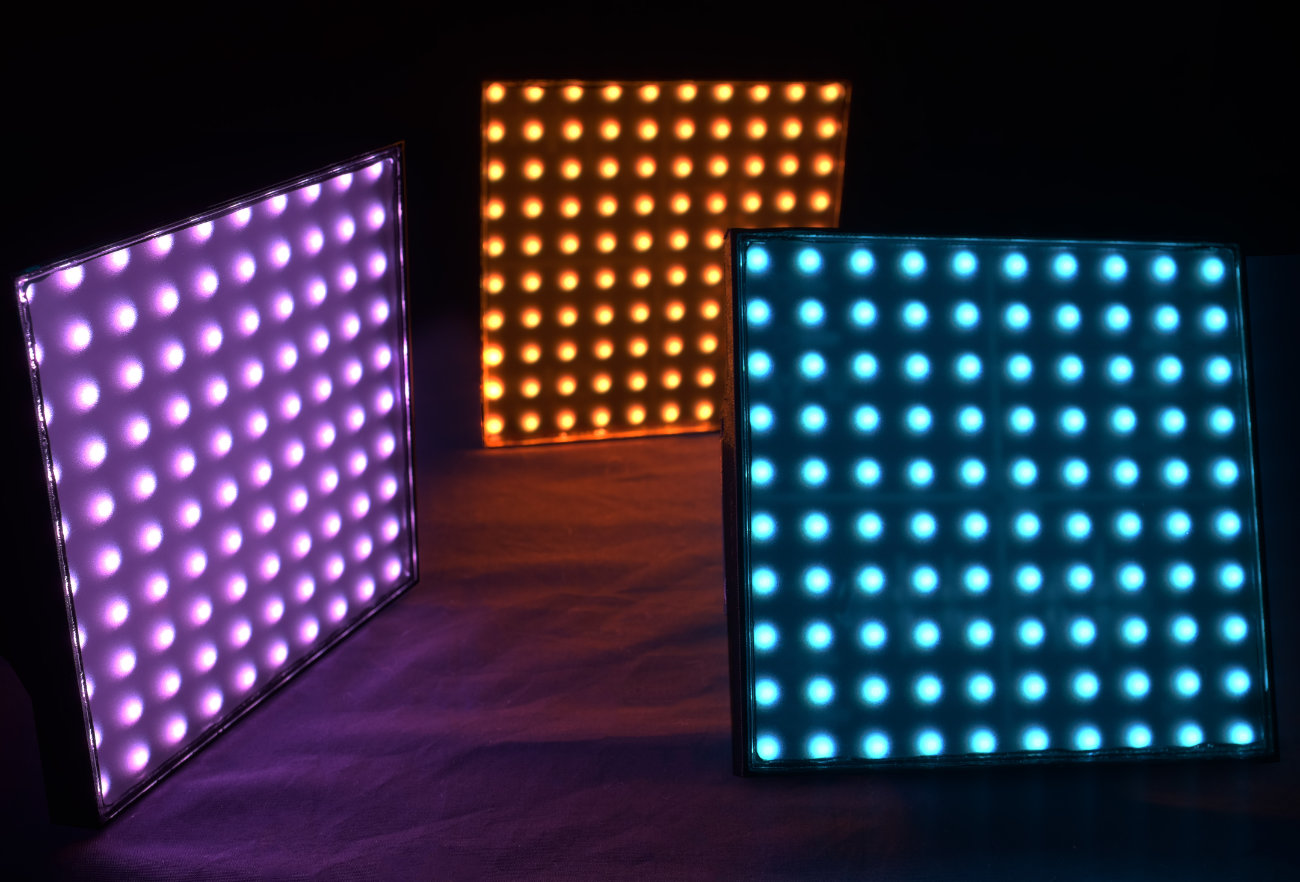

I linked up with Steve French from Volt Vision some 5 or so years ago, and we began collaborating some on various projects. One thing led to another, and I eventually hired him to help me take some of my DIY panels made from strips and upgrade to custom high current capable PCB arrays.

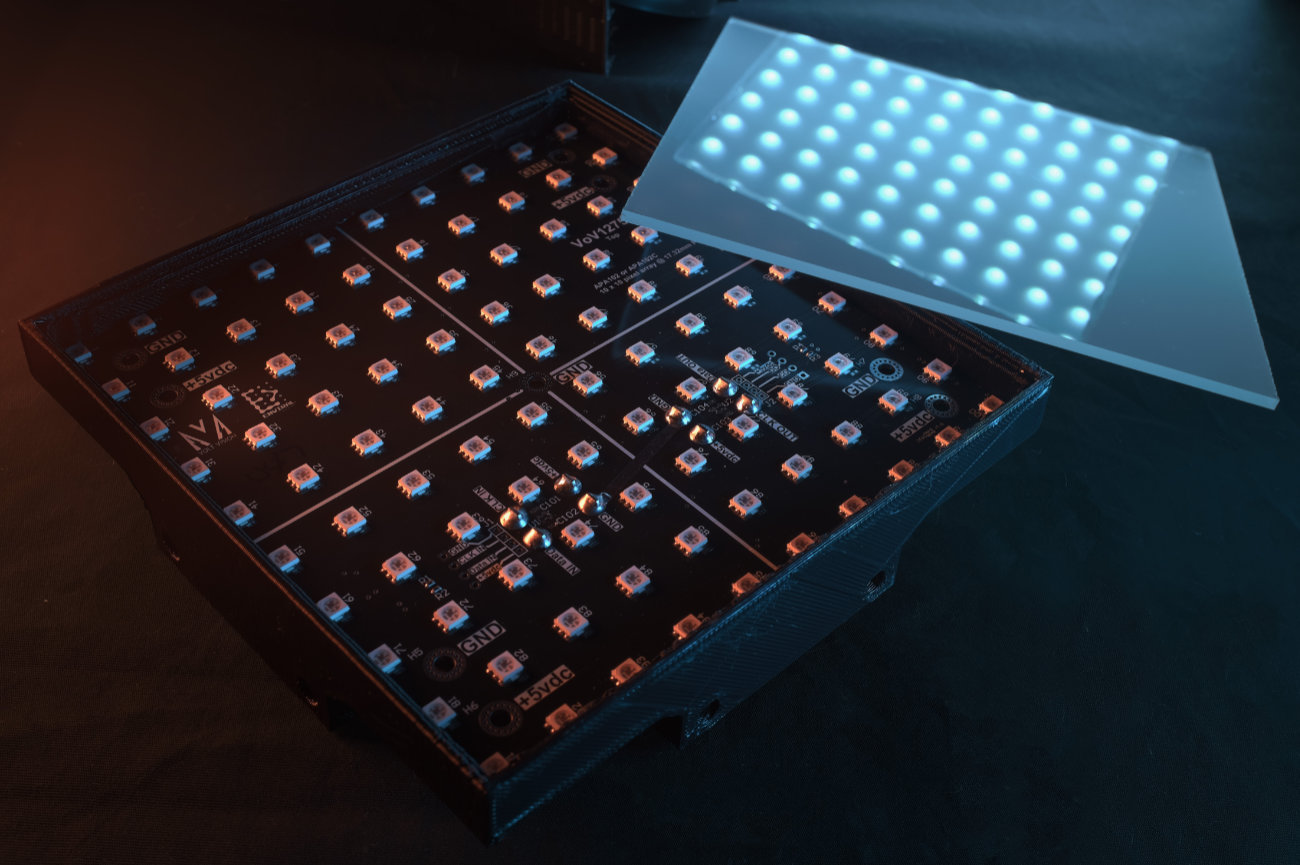

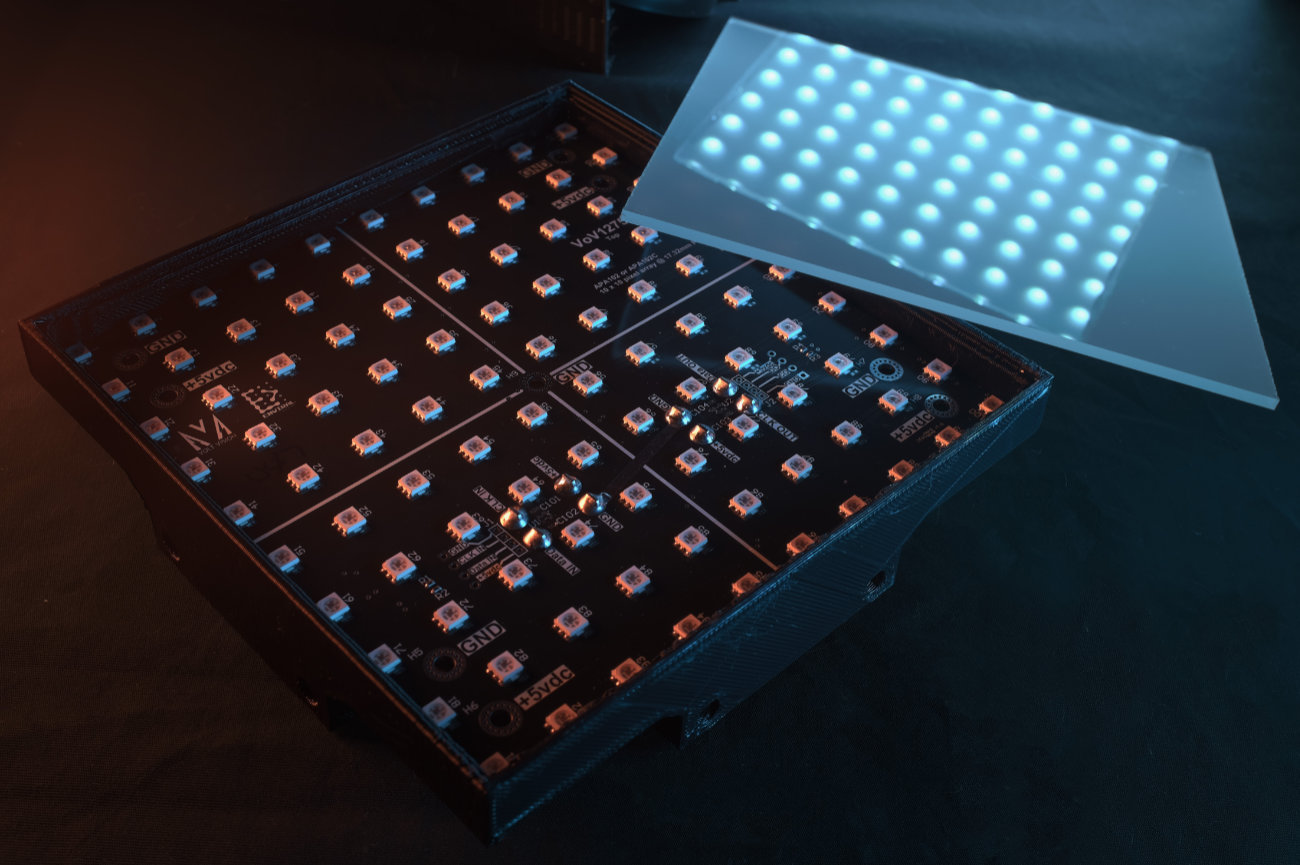

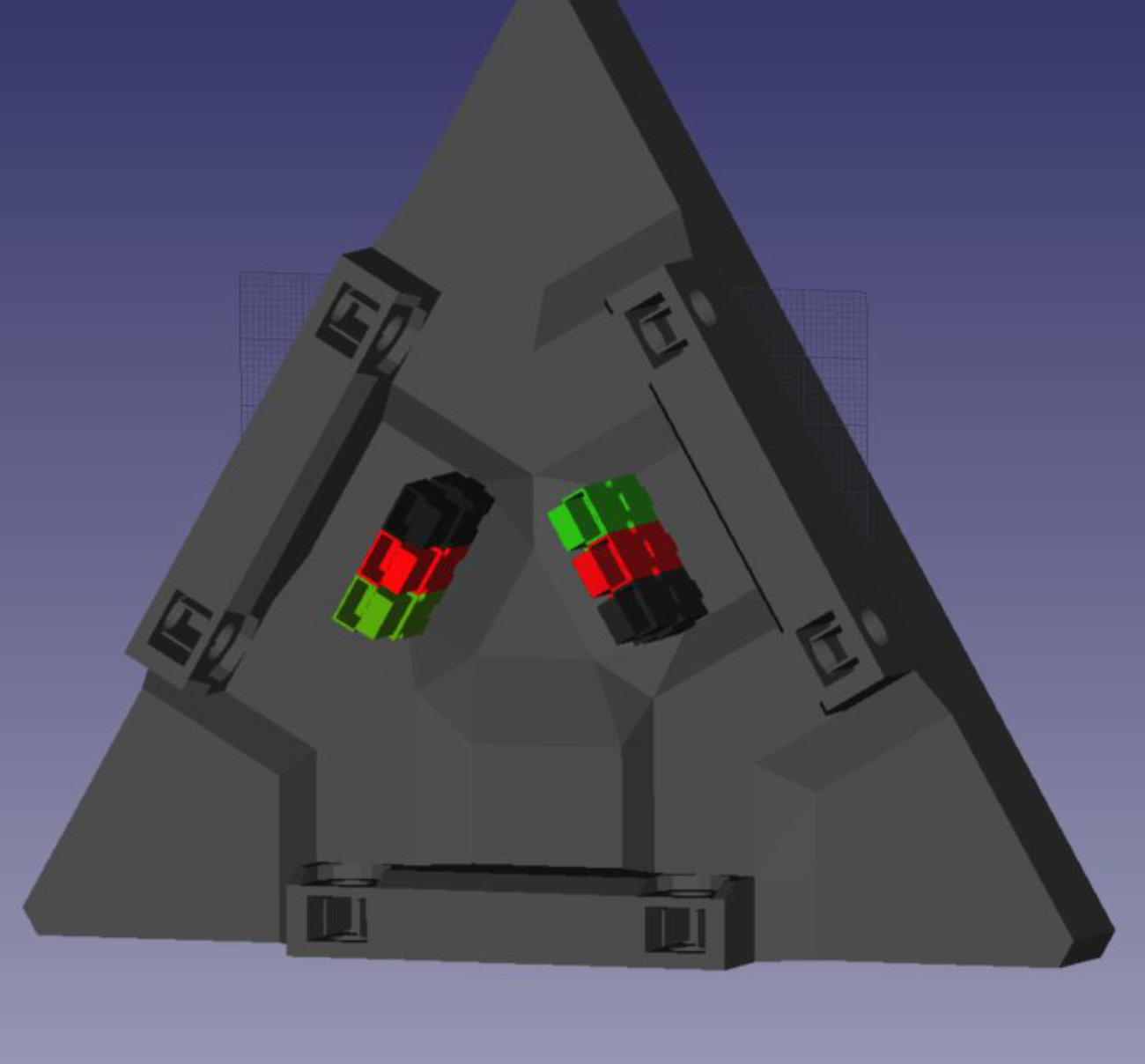

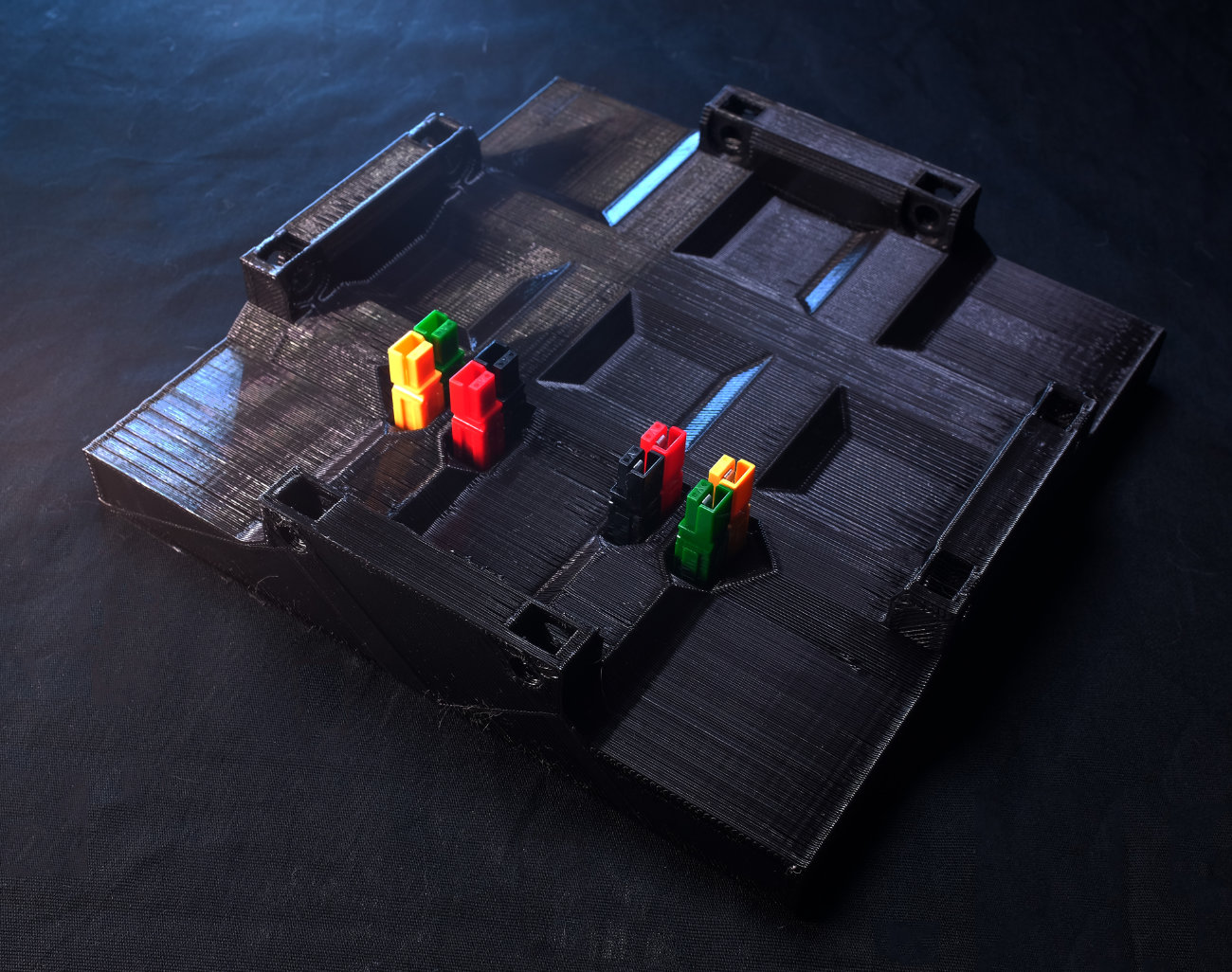

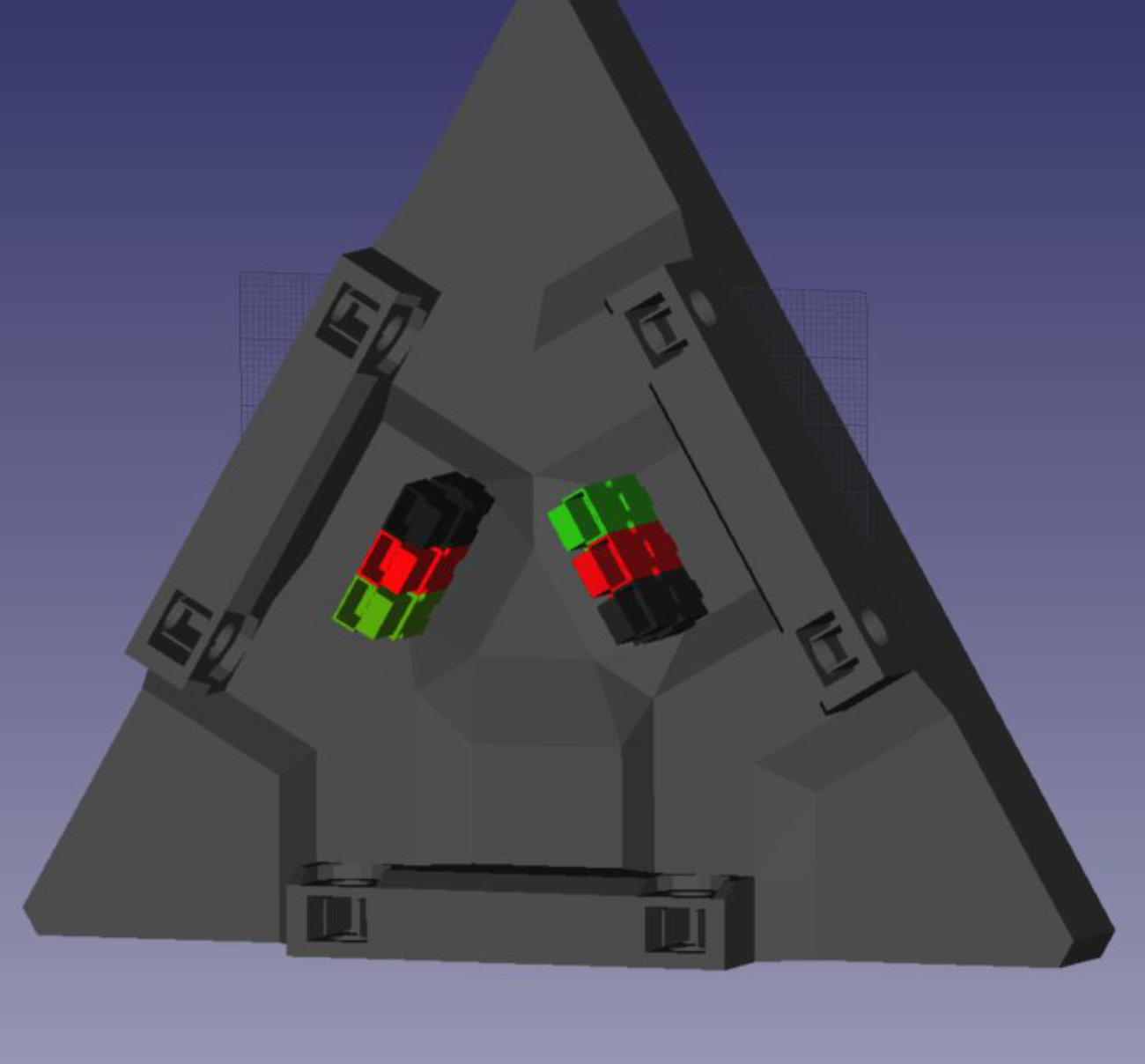

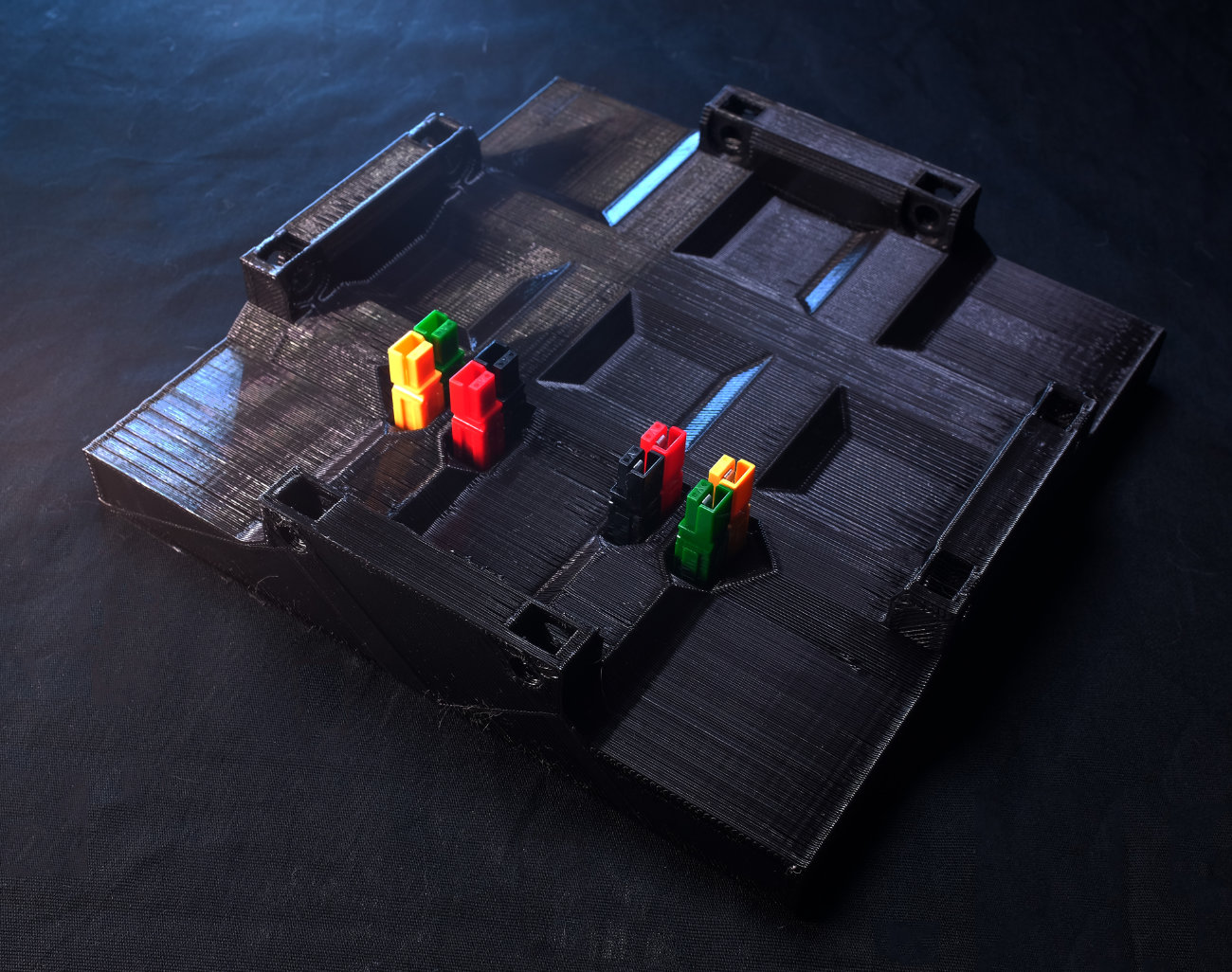

With these eventually in my hands, I began working on the enclosures for them, using the same Anderson Powerpole connectors I use on all my other plug and play equipment. They are also very friendly to high current.

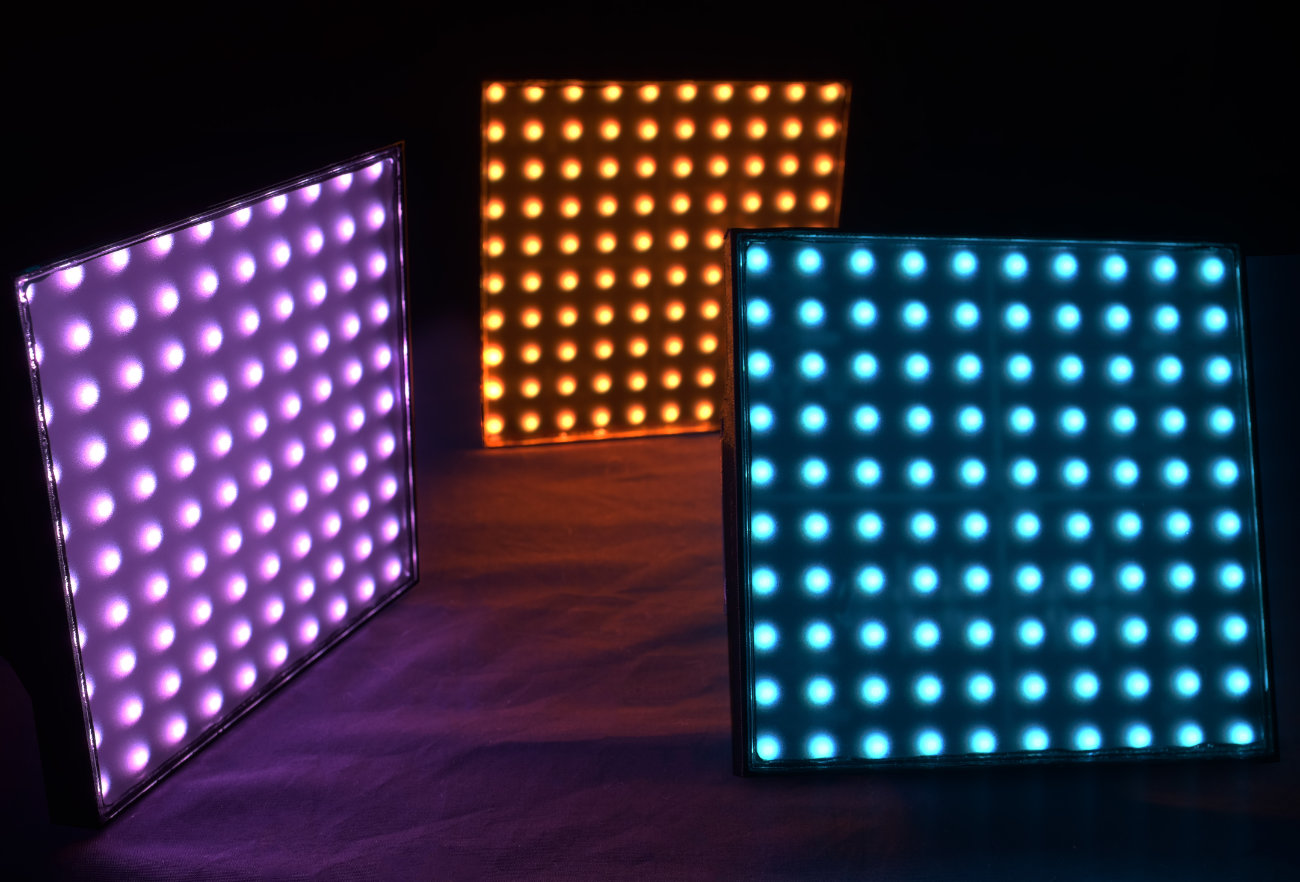

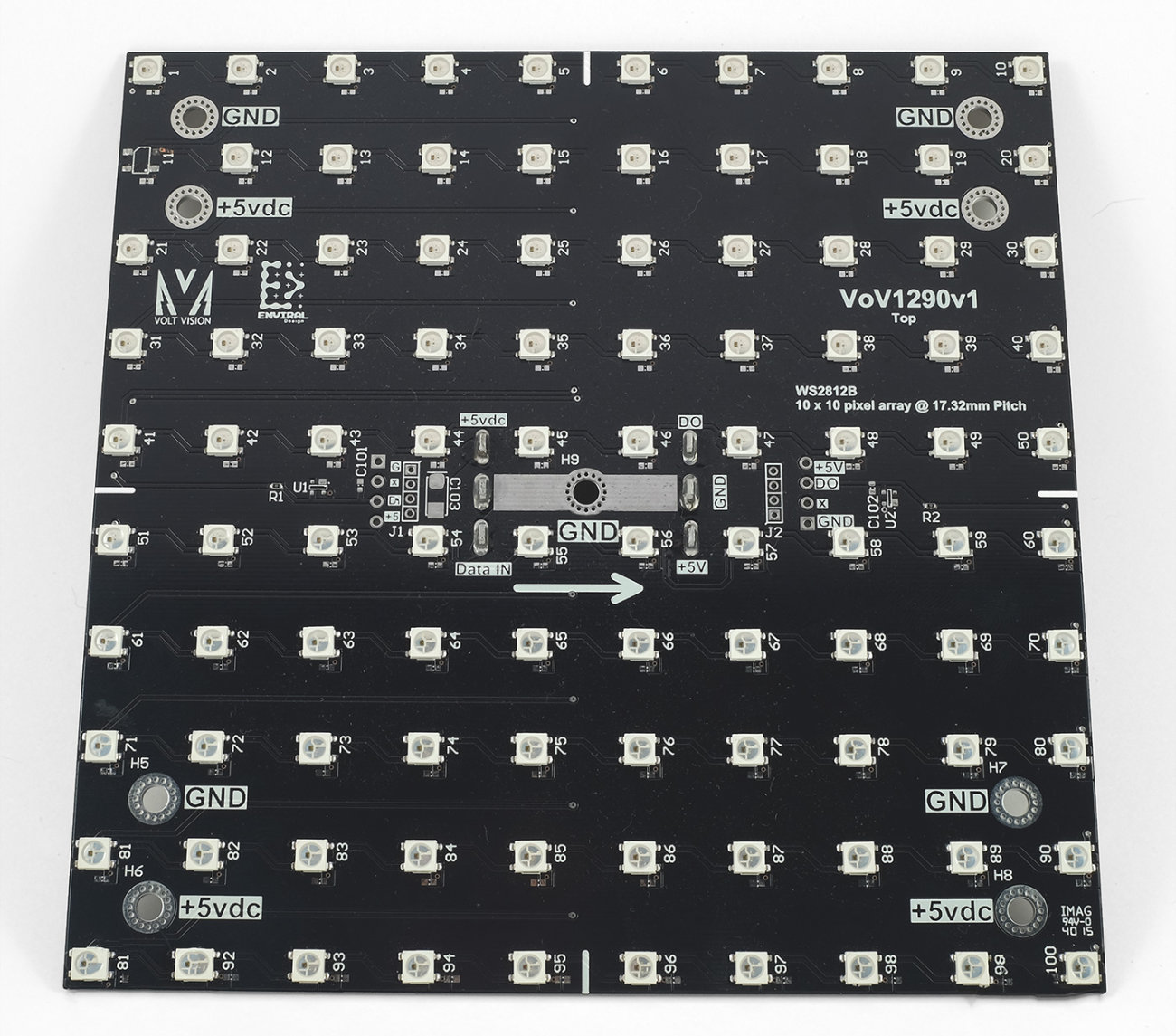

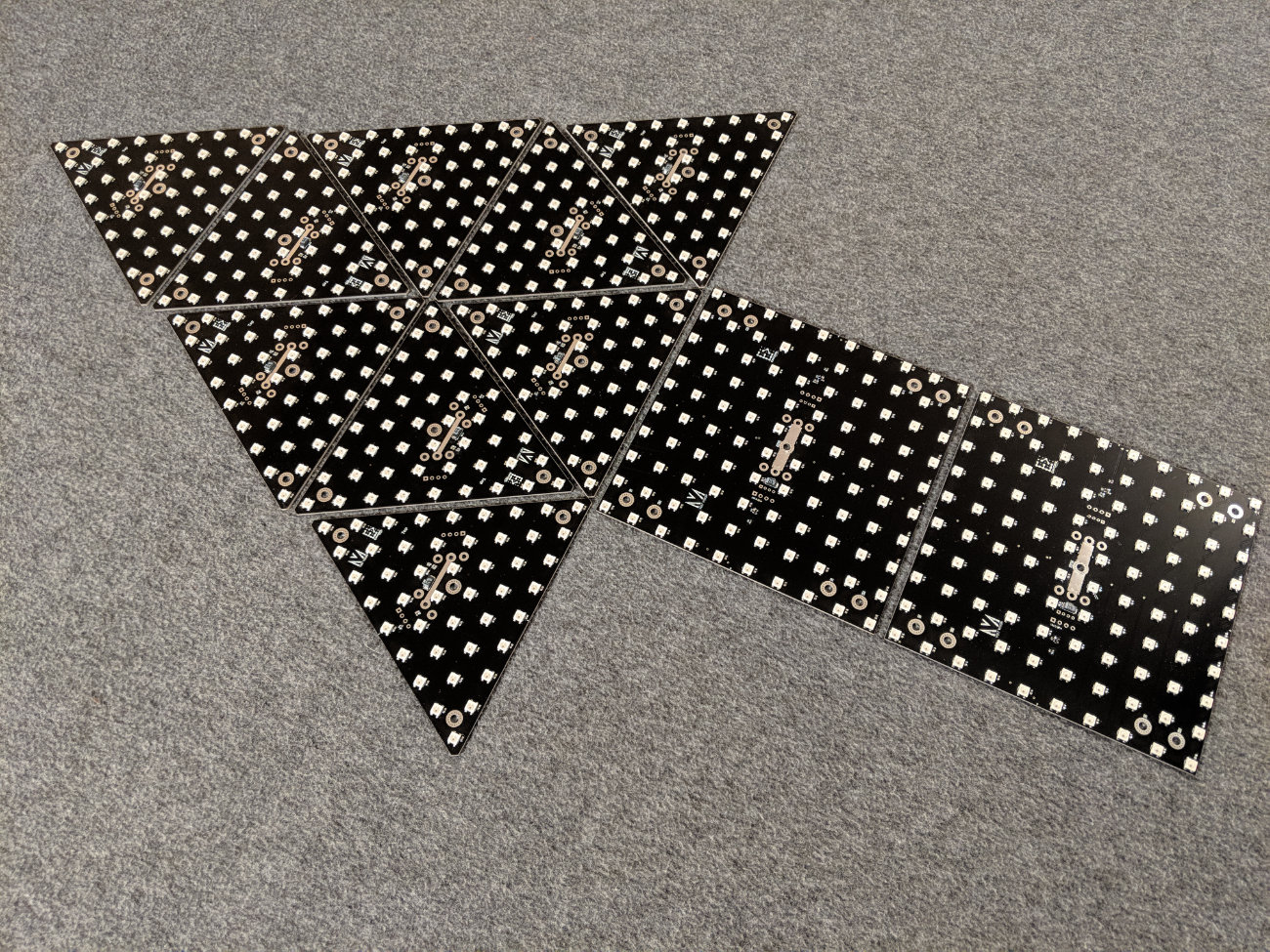

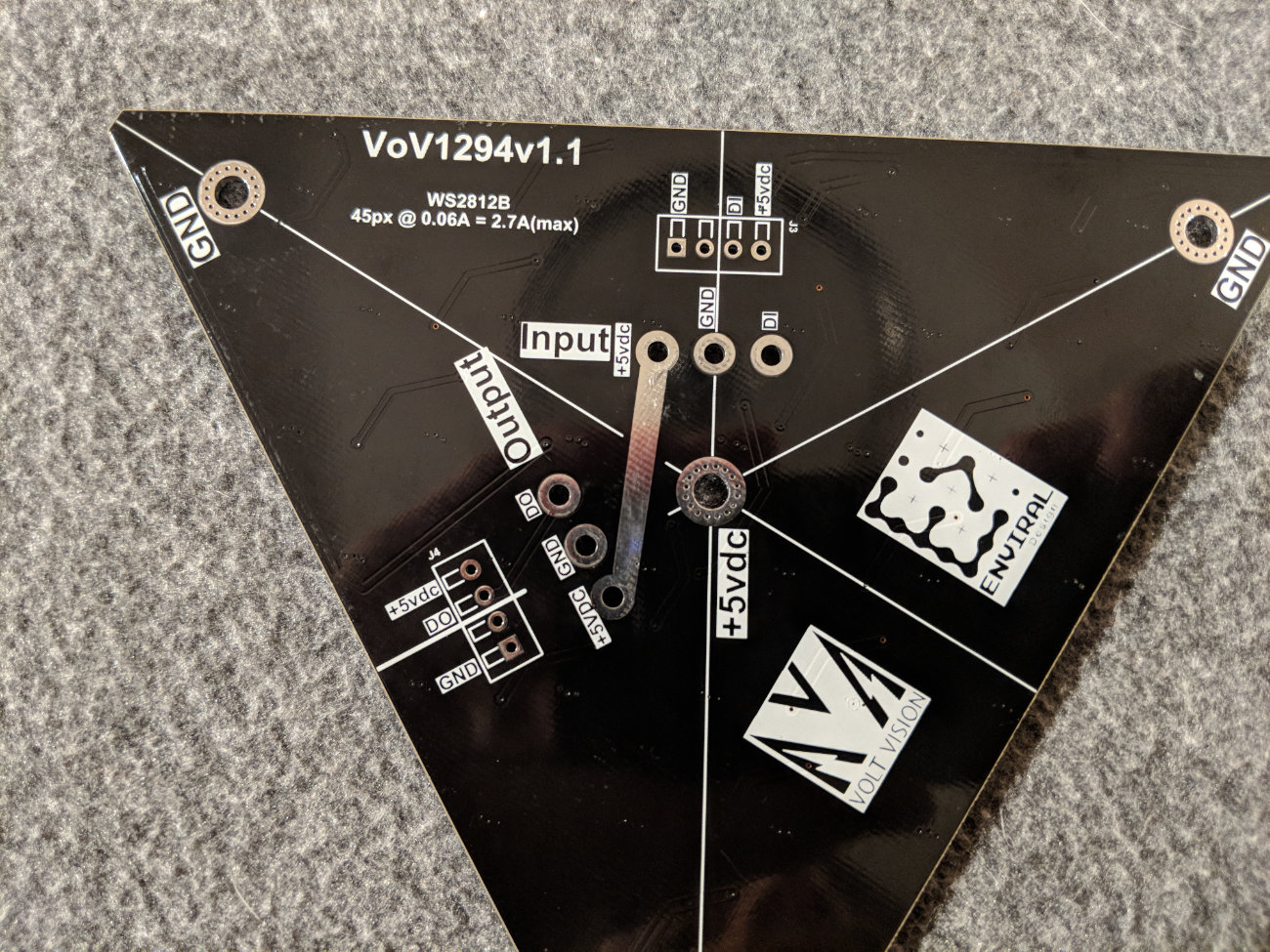

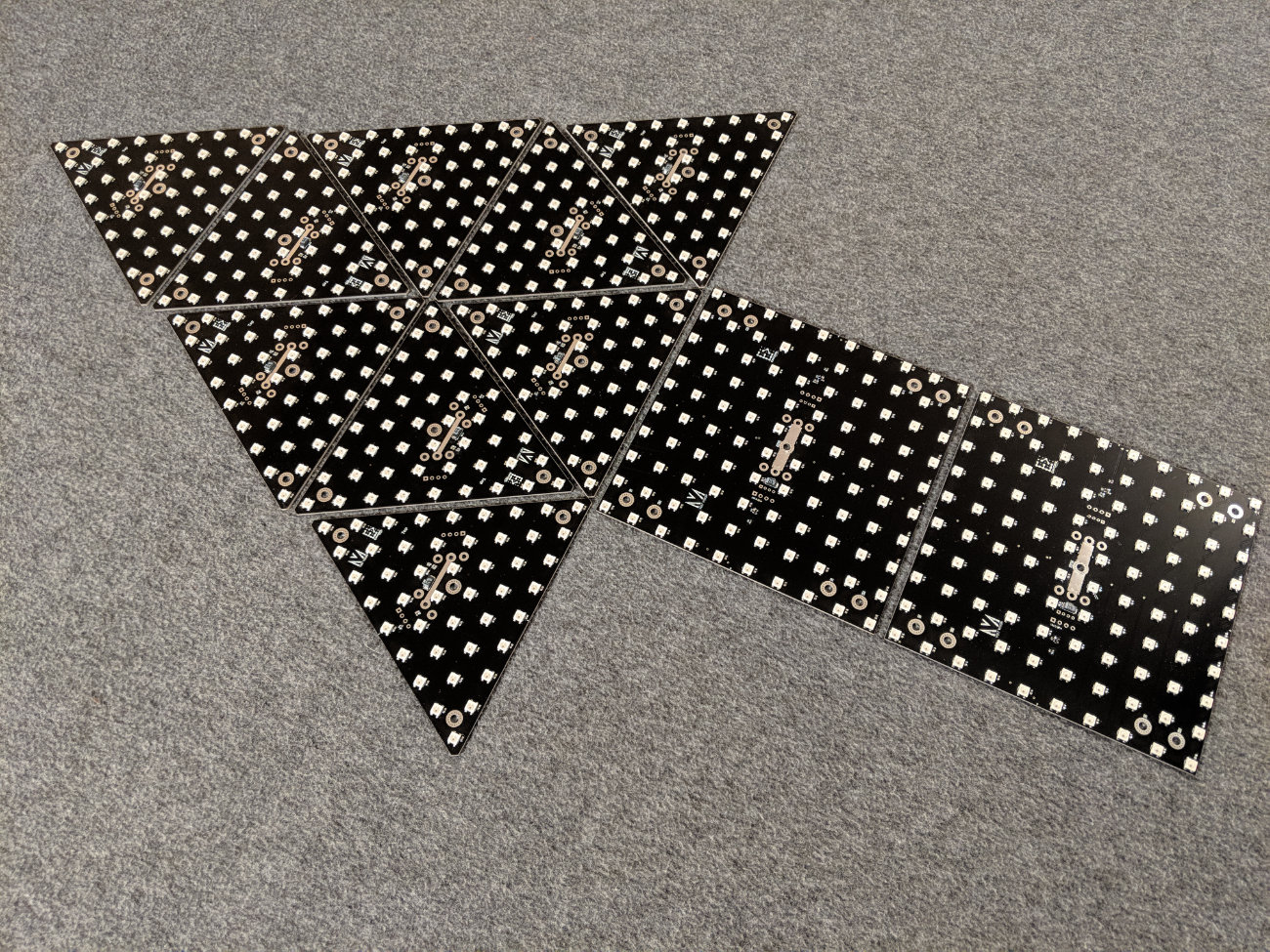

Anyhow, here are a few shots of the most up to date PCB's.

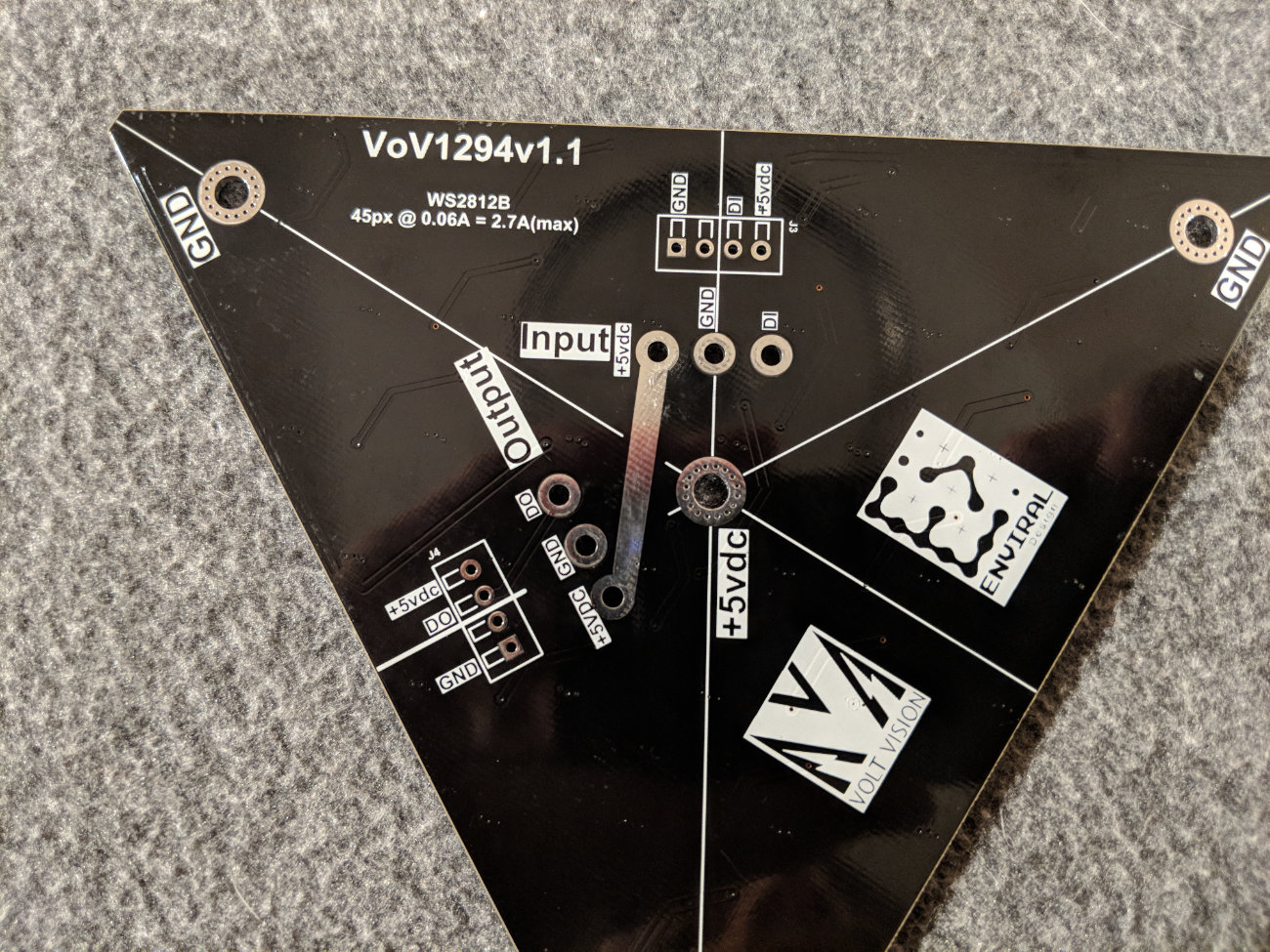

The idea here was to base these board's pitch off of the common 60/m led strip spacing. This made it possible for me to use these mixed in with my led strips in shows and projects with out worrying about uneven pixel density. Plus, ws2812b style leds are just so bright, it's hardly a good idea to have an array more dense than these with out dropping the brightness, which always tends to look too steppy for my taste.

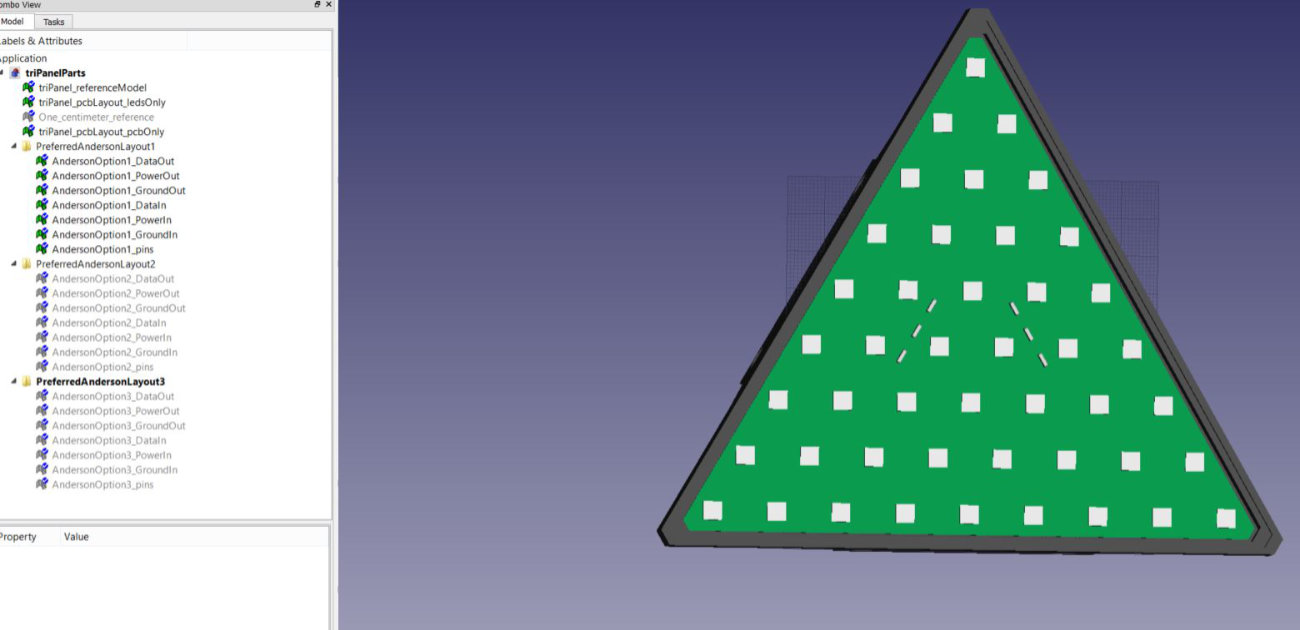

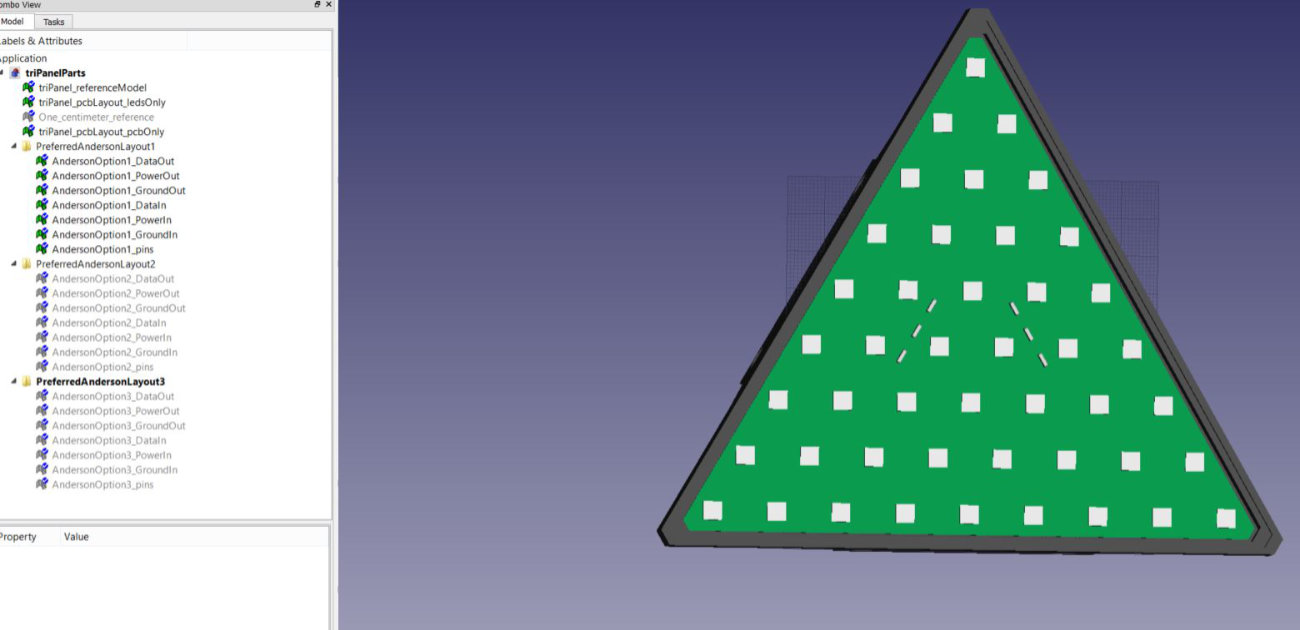

The PCB's needed an enclosure, so I iterated through many different versions of a fully 3D printed enclosure that could bolt together with other panels quickly and easily.

Another important feature these boards needed to have was the ability to tile, even between triangle and square, or square and square.

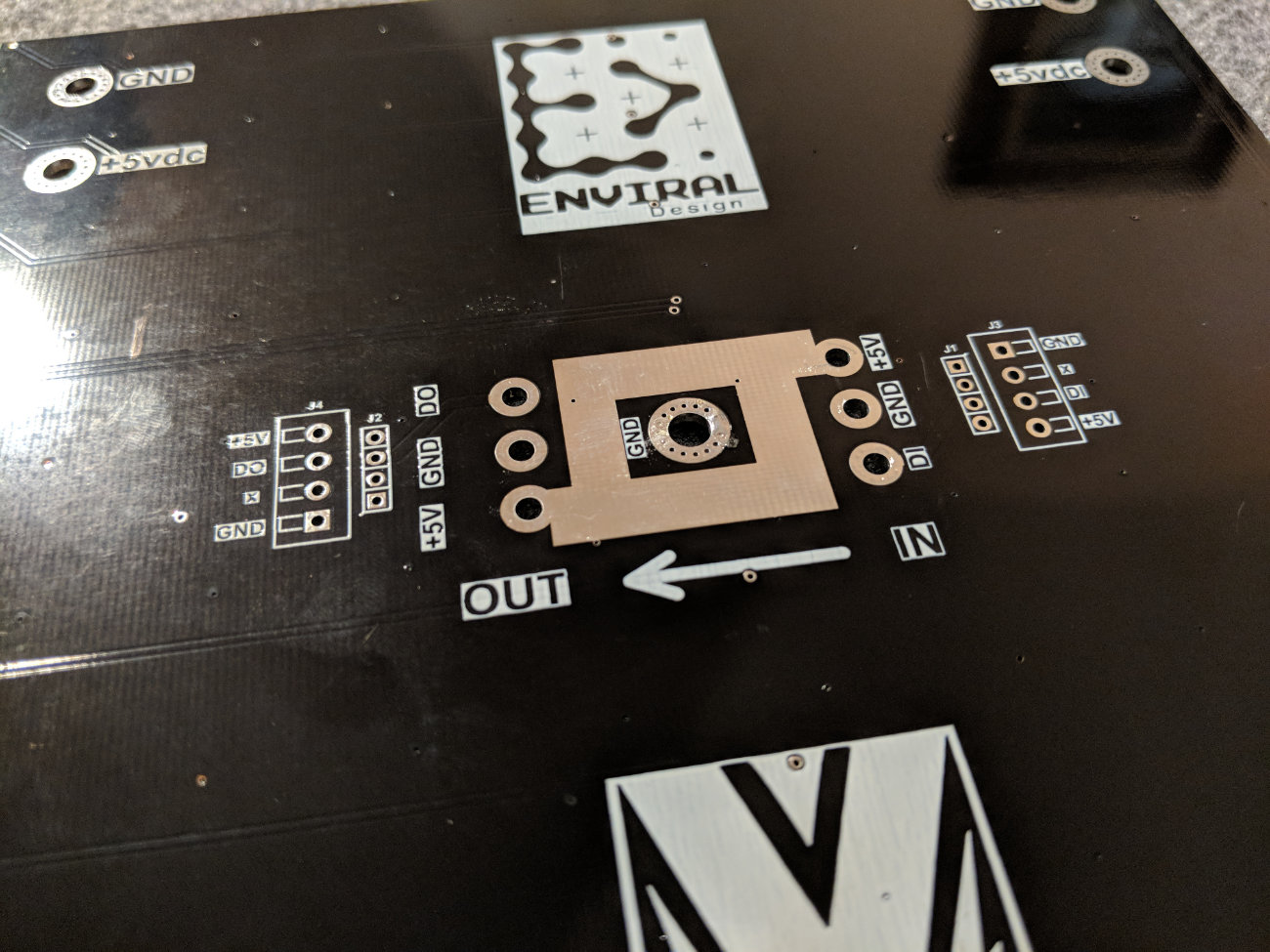

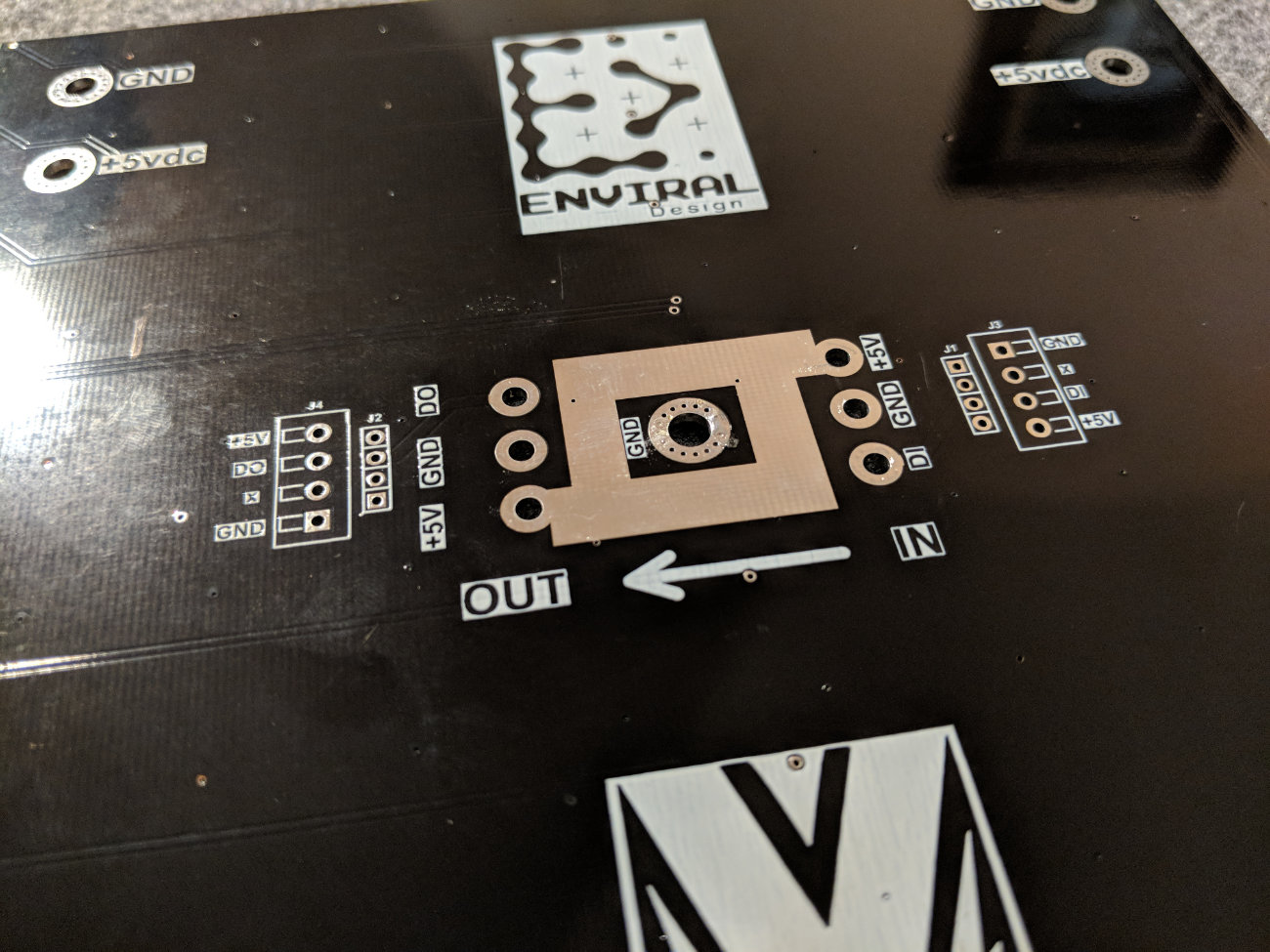

To help make these boards from contributing to voltage drop any more than they had to, We made the copper layer thicker and also incorporated a "solder lane" where more solder could be added, or even a big beefy piece of solid core copper, if needed to allow voltage to pass through unhindered.

Though generally longer cable runs are where the voltage get's lost the most, this was an easy add so we decided it was worth it given that a lot of high current stuff is tightly packed arrays of pixels too.